Pourquoi écrire sur la manière dont les vêtements sont fabriqués ? Vous regardez votre chemise, votre haut, votre pantalon préféré et vous vous demandez de quoi ils sont faits ? Du tissu, dites-vous ? Et ce fil provient du tissu. Mais comment est fabriqué le fil ? Il existe des types de fil qui peuvent être créés par une machine appelée machine à torsion de fil. Cette machine accélère le processus de fabrication de fil.

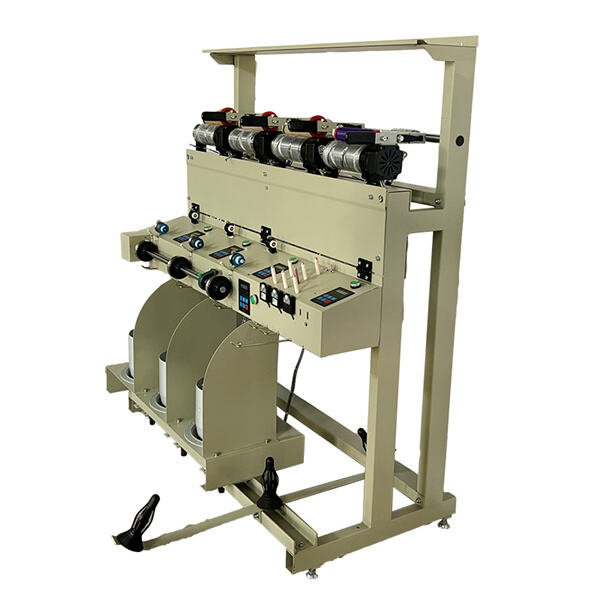

Autrefois, le fil était fabriqué en tordant ensemble des fibres avec un outil appelé fuseaux. C'était un système très long et coûteux en temps, qui ne donnait pas toujours un fil de haute qualité. Parfois, le fil était fragile ou irrégulier. Cependant, il existe désormais des machines qui peuvent torsader le fil de manière bien meilleure et à des vitesses beaucoup plus rapides. Ces types de XINDAWEI machine de bobinage automatique de fil sont capables de produire un fil plus solide et plus régulier que celui fabriqué à la main.

Une machine à torsion de fil tord les fibres pour fabriquer du fil. La torsion est une étape cruciale, car elle renforce le fil et le rend plus durable. Plus les fibres sont tordues serrées, plus elles adhèrent ensemble et, par conséquent, vous éviterez des ruptures fréquentes de fils lors du travail avec du fil pour créer des vêtements.

Magnétisme : Les anciennes méthodes de fabrication de fil signifient que la qualité du fil n'était pas toujours la même à chaque étape du processus. Cela avait ses avantages et ses inconvénients à certains moments. Une XINDAWEI machine d'enroulement de pelotes de fil , où les fibres sont tordues dans une direction constante en longueur. Cela signifie que le fil produit est de haute qualité et fiable.

Productivité : tordre manuellement les fibres est laborieux et chronophage. Sur une machine à tordre conçue pour la laine, il est possible de tordre de nombreuses fibres en même temps — et ainsi produire beaucoup de fil rapidement. Et plus vite ces XINDAWEI enrouleur de fil automatique fonctionnent, plus les usines de fil peuvent en produire, ce qui est pratique lorsqu'elles ont des commandes à honorer.

Les machines XINDAWEI sont alimentées par des moteurs à rotation rapide, capables d'atteindre 10 000 tr/min (tours par minute) ! Cette vitesse incroyable permet au fil de se rapprocher rapidement et uniformément, produisant un fil torsadé suffisamment solide pour toutes ses utilisations. Plus le nombre de fréquences de torsion (1) est élevé, plus la torsion des fibres est rapide, et meilleure est la qualité du fil.

Le premier s'appelle les rouleaux d'alimentation. Ce sont les rouleaux qui vont tirer les fibres dans la machine. Les fibres arrivent à l'intérieur de la machine et passent par un cadre appelé ébauchage. Ensuite, les fibres sont étirées par une machine spéciale pour les rendre aussi fines que possible avant d'être torsadées.

L'entreprise a obtenu la certification CE pour sa machine de torsion de fil. De plus, elle détient plus de 20 brevets sur la machine à enrouler du fil et le tambour rainuré, protégés par des droits de propriété intellectuelle indépendants. Elle a été désignée comme une « entreprise de haute technologie ».

Xindawei, machine à torsion de fil et équipement de bobinage de fil depuis plus de 20 ans. Son site de production mesure plus de 3000 mètres carrés et le département R&D est composé d'une équipe d'experts. Xindawei a développé un système d'automatisation professionnel et des systèmes de contrôle pour les données à utiliser sur les cônes-bobineurs et les machines à coudre pour le bobinage de fil. Cela garantissait que les machines répondraient aux exigences de ses clients. Ces produits sont très appréciés sur le marché domestique et exportés vers les États-Unis, l'Europe, le Moyen-Orient et l'Asie du Sud-Est.

Xindawei propose des conceptions personnalisées et uniques pour divers types de fils. Notre expérience en OEM s'étend sur plus de 20 ans. Pour les tambours à rainures, nous offrons une variété de modèles compatibles avec différentes machines à torsion de fil ou bobines. Nous fournissons également des enrouleurs de fil testés en laboratoire destinés aux machines de bobinage de fil.

Les instituts de recherche, les universités et les entreprises basées sur la technologie sont les principaux clients de notre machine à enroulement de fil. Plus de clients de machines à torsion de fil dans plus de 60 pays sont servis par cette entreprise.