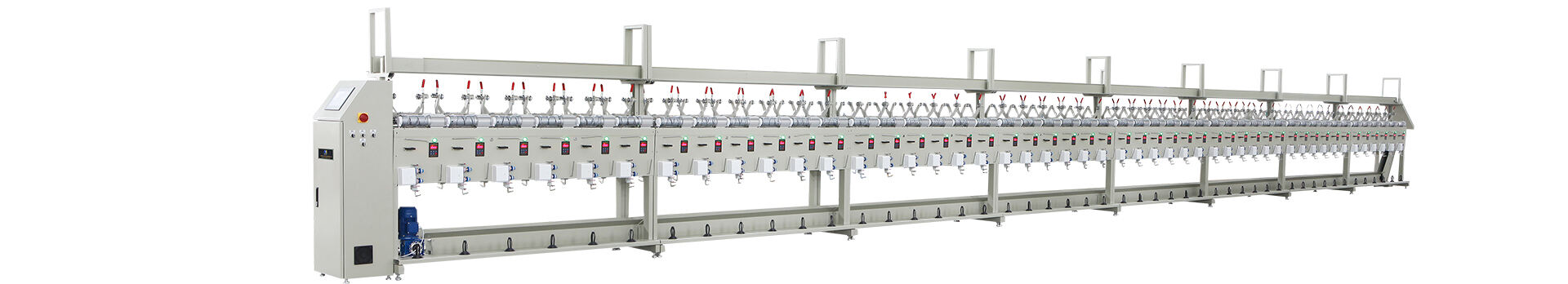

Single Spindle(Unit)

1. Automatic stop at preset diameter and at yarn break, speed up to 1200 mt/min.

2. Special winder for the production of hard cones for dyeing and waxing, for any type of yarns & blends.

3. Slow start and progressive speed increase, adjustable winding tension with frequency variator, mechanical clearers, yarn tensioners and anti-patterning device.

4. Supplied in sections of 1 up to 108 heads ready for opearation.

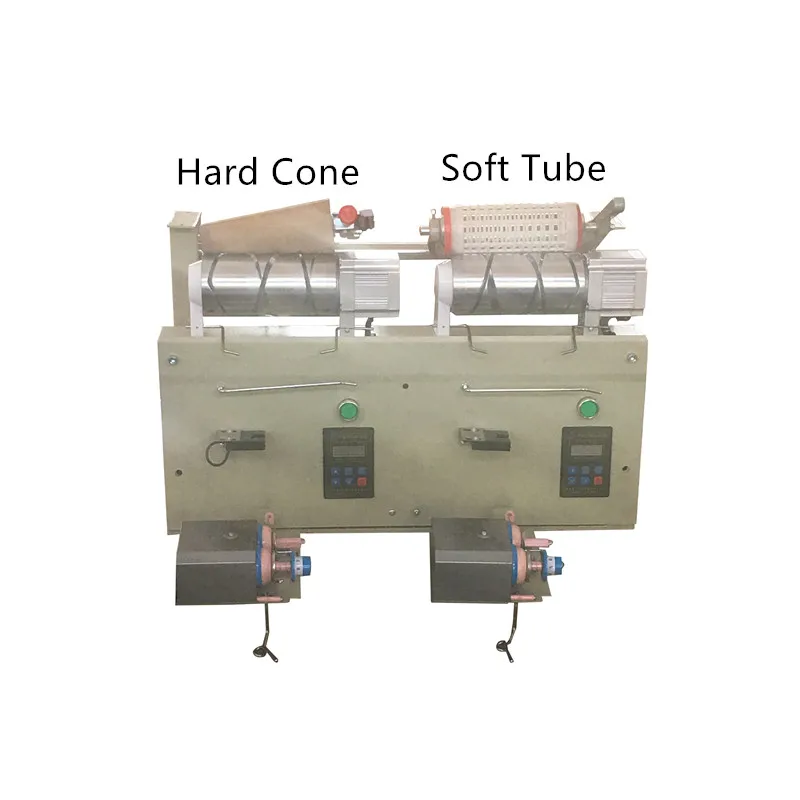

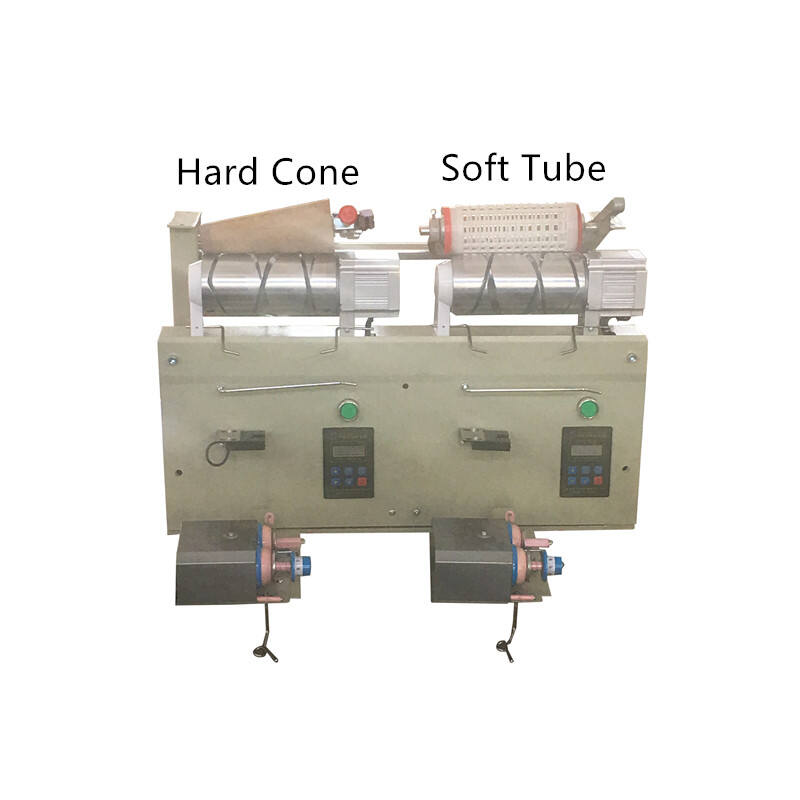

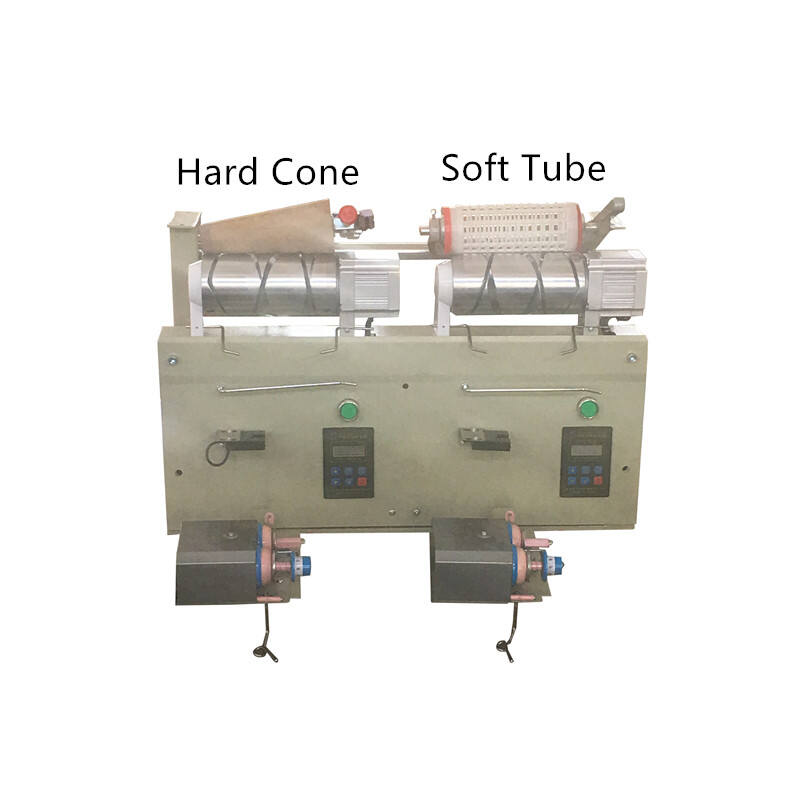

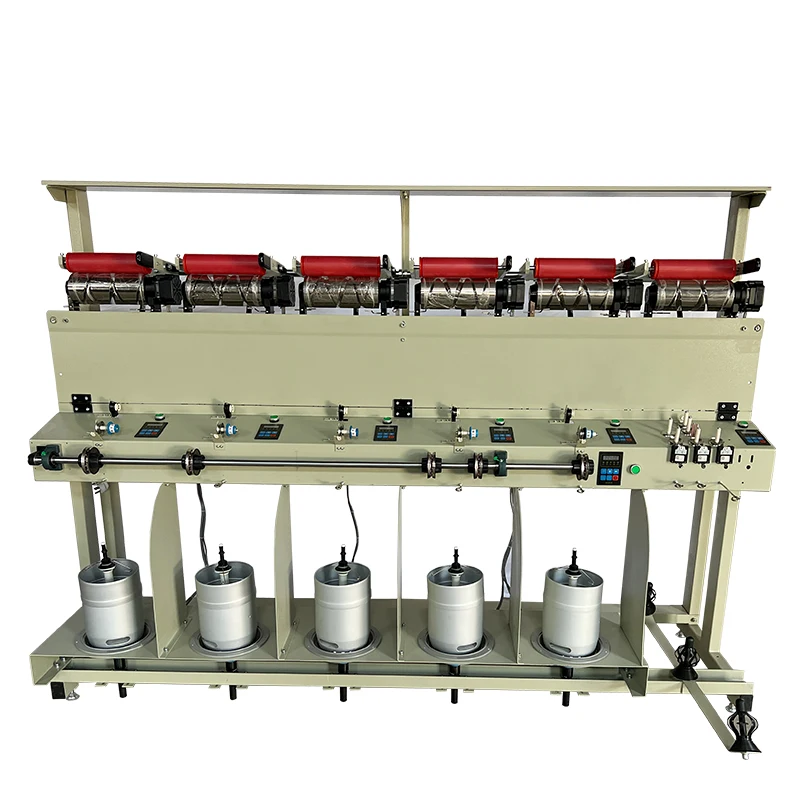

2 Spindles(Units)

1. Automatic stop at preset diameter and at yarn break, speed up to 1200 mt/min.

2. Special winder for the production of hard cones for dyeing and waxing, for any type of yarns & blends.

3. Slow start and progressive speed increase, adjustable winding tension with frequency variator, mechanical clearers, yarn tensioners and anti-patterning device.

4. Supplied in sections of 1 up to 108 heads ready for opearation.

LZ-M-L-J

1. Vertical winder path with no inflection point, little friction and less hairiness.

2. Special motor with longer axis can prevent yarn twisting, speed controlled by inverter.

3. Double points tension control system with micro motors, uniform yarn tension.

4. Using high quality alloy drums with optimized groove shape, which has the advantages of good anti-overlapping characteristics, light weight, good wear resistance, and static elimination.

5. Single winding motor control for each spindle.

6. High-speed creel with gas spring, which can keep constant winding pressure. This creel is stable and reliable.

7. The traverse device for making the soft edge is very easy to adjust, that will make the loose bobbin be suitable for even dyeing.

Item |

Technical parameters |

|

|

Types of winding |

Drum,Random |

|

|

Mechanical speed |

Up to 1200m/min (process speed depending on quality of yarn and feed packages) |

|

|

Package shape |

Cylindrical or conical |

|

|

Traverse length |

150mm, 152mm, 154mm |

|

|

Mechanical anti-patterning system |

Swing amplitude of creel :1-3mm |

|

|

Package bobbin |

0°ï¼3°30âï¼4°20âï¼5°57âï¼9°15â² |

|

|

Package diameter |

Up toÏ 290 mm |

|

|

Package density |

0.2-0.4g/cm3 |

|

|

Fibre / count |

Cotton.flax, wool, silk,chemical fiber /Ne 6â¦180 |

|

|

Auto stop while yarn break |

With electronic yarn detector,the spindle will stop when yarn break |

|

|

Slow start |

For smooth start and better winding quality,supportting individual slow start for each spindle(available on request) |

|

|

External dimensions |

2.235(length) Ã0.7(width) Ã1.68(height) |

|

|

Power supply |

3 phased 380V±10% ï¼50/60HZ |

|

|

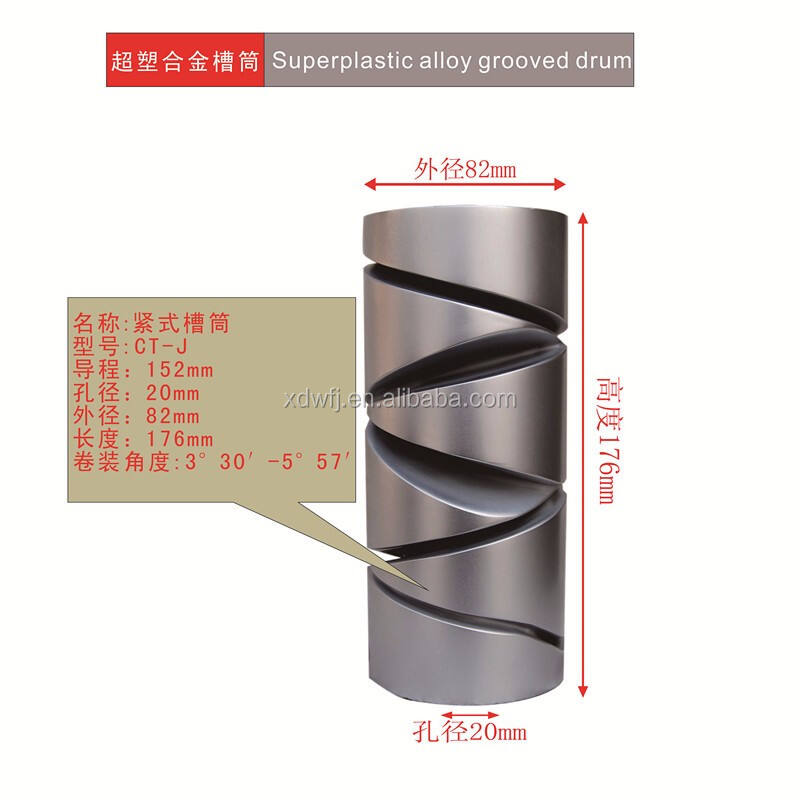

Super Plastic Winding Drum

Lead: 152mm

Outer diameter: 82mm

Length: 176mm

Turns: 2 .5

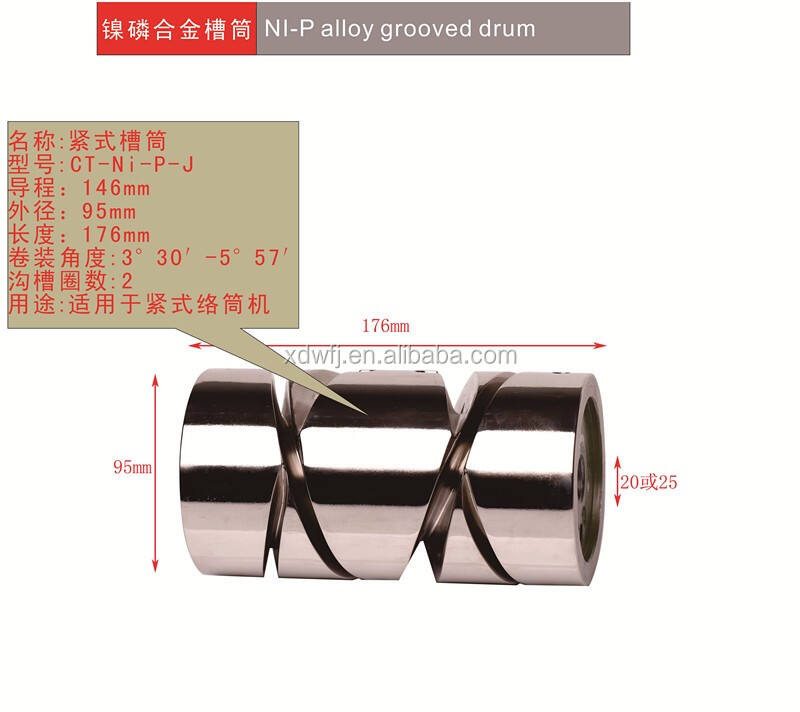

Ni-P Alloy Winding Drum

Lead: 146mm

Outer diameter: 95mm

Length: 176mm

Turns: 2

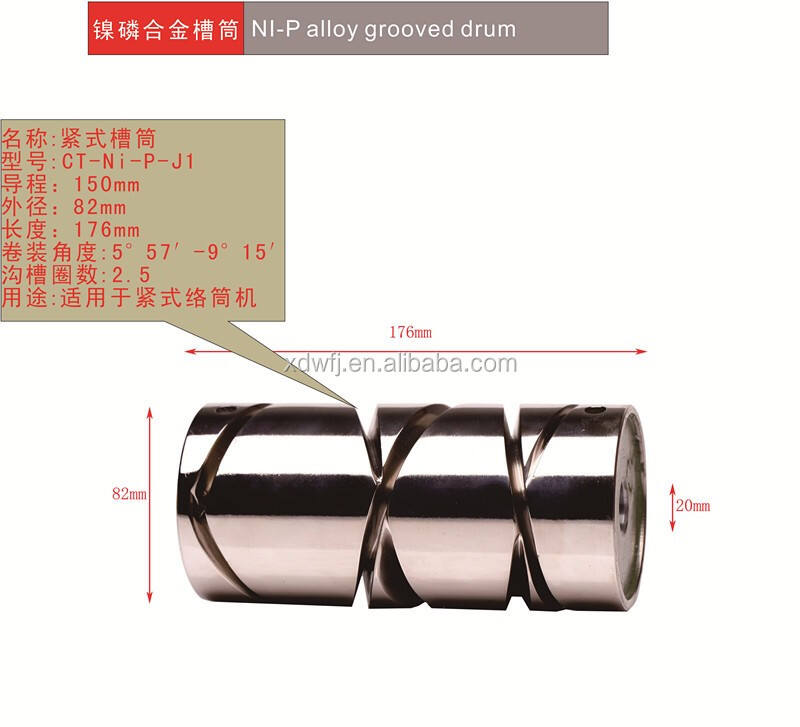

Ni-P Alloy Winding Drum

Lead: 150mm

Outer diameter: 82mm

Length: 176mm

Turns: 2.5

XINDAWEI

The Two Spindles of Yarn Winding Machine is an innovative and dependable product to generally meet yarning and demands weaving textile companies. The equipment provides a competent and easy method of various kinds of yarns into cones for further processing. This winding yarn advanced suitable for industrial use and guarantees superior performance for a range of yarning activities.

The Two Spindles of Yarn Winding Machine from XINDAWEI allows users to wind multiple cones of yarn at a time, which translates to increased effectiveness, productivity, and profitability with two spindles. It is made for handling diverse yarn, including silk, wool, cotton, and artificial fibers.

The operates Two Spindles of Yarn Winding Machine with two spindles rotating simultaneously. This eliminates the requirement for manual intervention, thus saving effort and time. Its motor was created to deliver high torque crucial in handling dense and heavy yarns.

XINDAWEI Two Spindles of Yarn Winding Machine is produced with an easy-to design-use. The yarn is given through the feeding tubes the equipment, where it is automatically wound onto the cones. The equipment's tensioning system ensures a consistent and yarn uniform winding. The cones are then ejected automatically, requiring manual minimal intervention.

The Two Spindles of Yarn Winding Machine features a digital control that allows users to create winding speeds, yarn tension, and spindle placement. The panel displays facts about the device's performance and provides an user user-friendly interface easy operation.

XINDAWEI's Two Spindles of Yarn Winding Machine is made with robust and durable materials to make sure long-term reliability serviceability. The motor system is engineered for a long lifespan low noise levels and energy efficiency.

EN

EN

AR

AR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV TL

TL IW

IW ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI ET

ET HU

HU TH

TH TR

TR MS

MS BE

BE KA

KA BN

BN KK

KK TG

TG UZ

UZ